Aluminium Square Tube

Zhongchuang Architectural is professional China customized aluminium square tube manufacturers suppliers and factory, specialized in providing discount aluminium square tube with wholesale bulk price. For quotation, contact us now.

1.25 inch square aluminum tubingRead More

1.25 inch square aluminum tubingRead More 1.5 x1 5 aluminum square tubingRead More

1.5 x1 5 aluminum square tubingRead More extruded square tubeRead More

extruded square tubeRead More 1.5 inch square metal tubingRead More

1.5 inch square metal tubingRead More 4 inch square aluminum tubingRead More

4 inch square aluminum tubingRead More 6x6 aluminum square tubeRead More

6x6 aluminum square tubeRead More anodized aluminum square tubeRead More

anodized aluminum square tubeRead More aluminium square tube blackRead More

aluminium square tube blackRead More 1 2 x 1 2 aluminum square tubeRead More

1 2 x 1 2 aluminum square tubeRead More bending square metal tubingRead More

bending square metal tubingRead More

- 1

- 2

What is Aluminium Square Tube?

An Aluminium Square Tube is a hollow, four-sided metal profile extruded from various aluminum alloys [3]. Known for being lightweight yet high-strength, it offers excellent corrosion resistance and aesthetic appeal for structural and decorative use [2].

Aluminium Square Tube Types

Aluminium Square Tube is categorized by their manufacturing process and alloy composition:

-

Extruded vs. Seamless: Extruded tubes are common for general construction, while seamless tubing is utilized for high-pressure applications requiring maximum structural integrity [1].

-

Alloy Series: The 6000 series (like 6061 or 6063) is the most popular due to its excellent weldability and corrosion resistance [5].

-

Finish Types: Available in mill finish, anodized, or powder-coated options to enhance durability and design versatility [10].

-

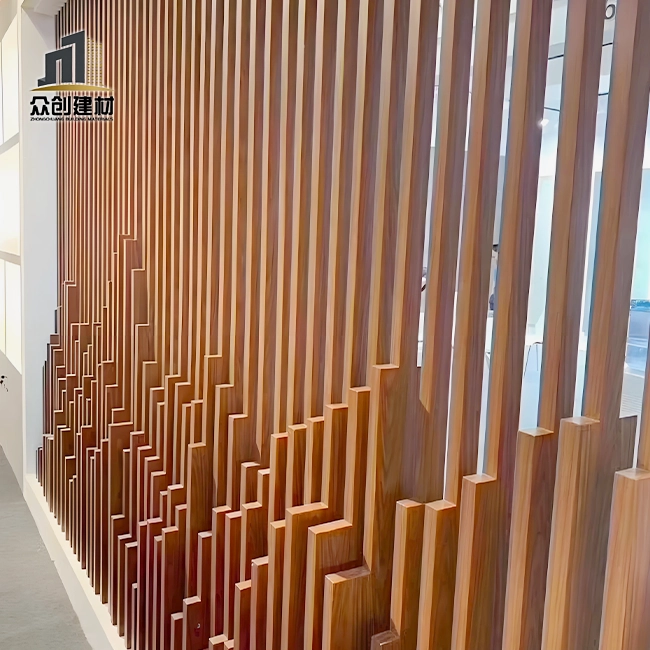

Dimensional Varieties: Ranging from small decorative 1-inch tubes to heavy-duty industrial sizes [8].

Quality Control

To ensure precision, manufacturers implement strict quality control involving:

-

Dimensional Tolerance: Verifying wall thickness and squareness using precision calipers.

-

Material Testing: Ensuring the alloy composition meets ASTM standards [1].

-

Surface Inspection: Checking for extrusion marks, scratches, or pits to maintain aesthetic quality.

Aluminium Square Tube Application

Due to their versatility, these aluminium square tube are essential in:

-

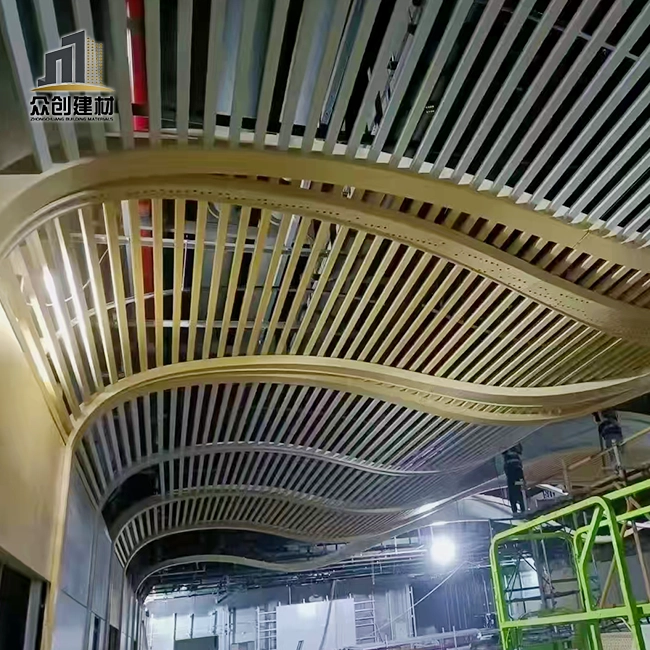

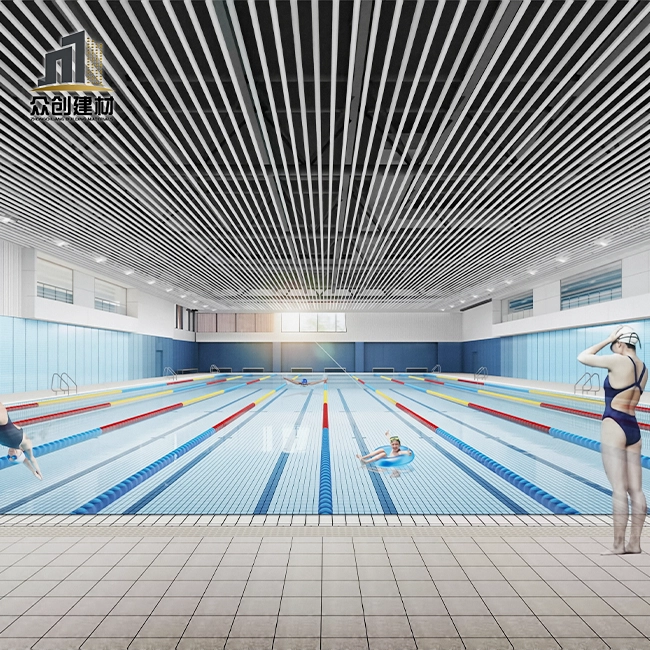

Construction: Used for window frames, curtain walls, and support structures to make buildings lighter [2].

-

Industrial: Framework for machinery, solar panel racks, and heat dissipation systems [9].

-

Transportation: Lightweight frames for trailers and automotive components.

-

Design: Modern furniture, signage, and retail displays where "easy processing" and "corrosion resistance" are vital [6].

FAQ

Q: What are the main advantages? A: They are lightweight, high-strength, corrosion-resistant, and cost-efficient [6][10].

Q: Can they be customized? A: Yes, many suppliers offer custom cutting, specialized alloys, and unique finishes [4][5].

Q: Are they suitable for outdoor use? A: Absolutely. Aluminum naturally forms a protective oxide layer, making it highly resistant to rust and weathering.

Would you like me to help you draft a specific quote request or technical specification sheet for these tubes?

Sources

-

mcknightsteel.com - Aluminum Extruded Seamless Tubing in Philadelphia, PA

-

qsfullmetal.com - Aluminum Square Tube: Applications In Construction and ...

-

chalcoaluminum.com - Aluminum Square Tube Purchase/Cutting/Customize

-

tri-stateal.com - Tri-State Aluminum: Custom Aluminum Extrusions ...

-

hugh-aluminum.com - Aluminum Square Tube: Advantages and Disadvantages

-

qst-corp.com - Metal Stamping & Aluminum Extrusion | Quality Stamping ...

-

bobcometal.com - Advantages You Do Not Know About Aluminum Square Tube

_1762768699969.webp)