Bending Square Metal Tubing: Best Methods for Precision Fabrication

In present day development and plan, usefulness progressively blends with aesthetic expression—and few forms exemplify this collaboration way better than bending square metal tubing Whether you’re forming enriching ceiling bends in a tradition center or making an rich railing for a extravagance stairway, bended aluminum tubing gives quality and natural stream. Bowing strategies permit inflexible, precise shapes to take on smooth, adjusted forms without relinquishing auxiliary astuteness. This web journal investigates the best creation strategies, common questions around the hone, and how square aluminum tubing can be changed into bended structural magnum opuses through gifted accuracy bending.

Why Is Bending Square Metal Tubing Important in Architectural Design?

How Does Bending Square Metal Tubing Enhance Modern Structures?

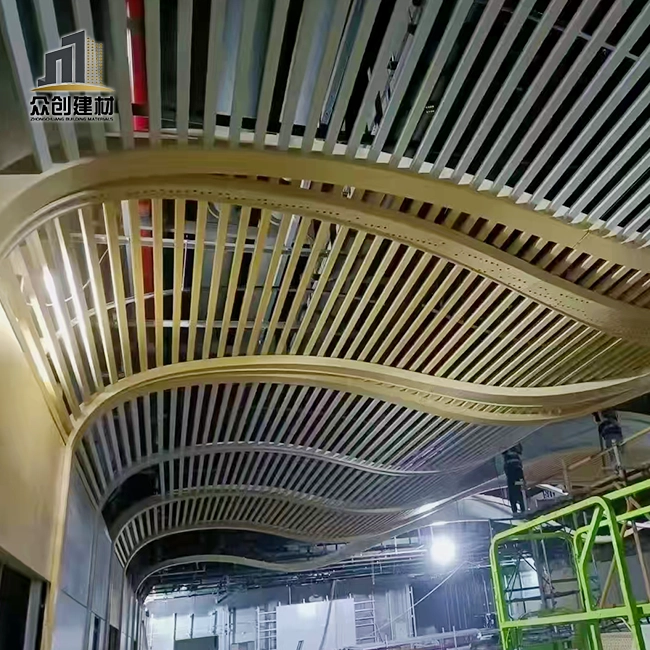

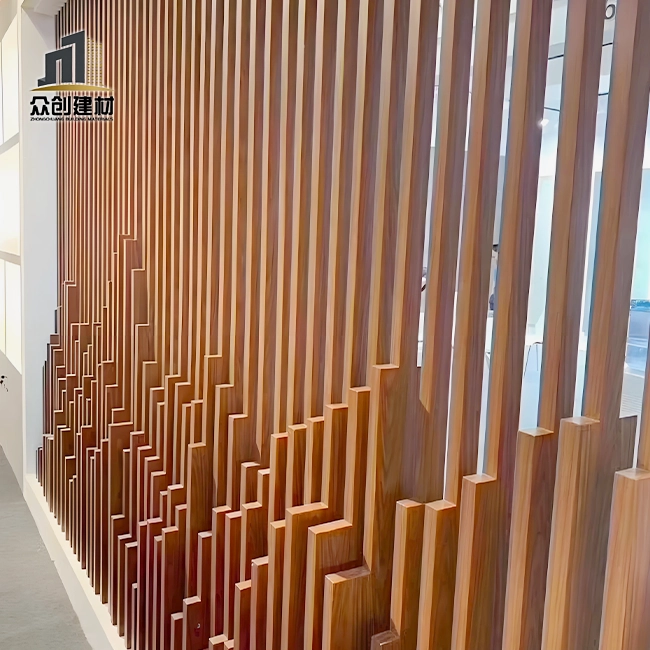

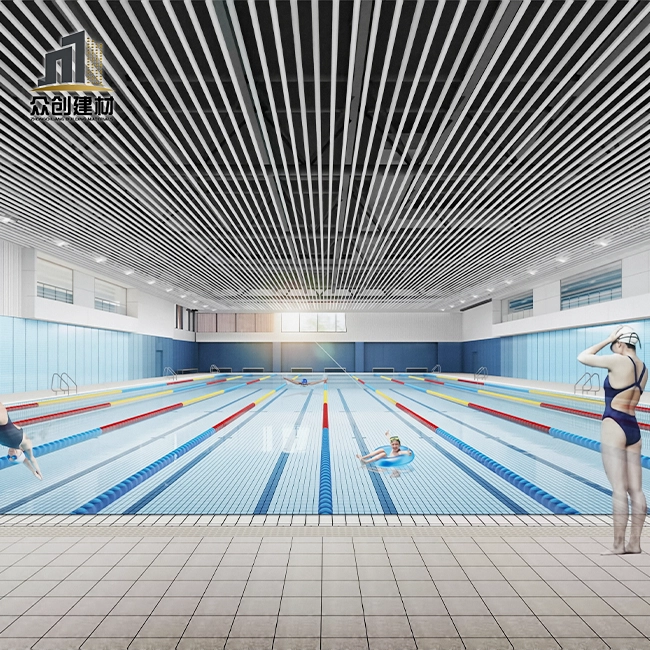

Bending square metal tubing presents a liquid tastefulness into something else unbending or geometric plans. In structural applications like lodging staircases, stop entrance curves, or suspended ceiling components in air terminals, bended aluminum includes natural delicateness to advanced structures. Or maybe than depending on sharp, straight traces, creators progressively look for streaming moves that direct sightlines and human development. Bended tubing empowers auxiliary and enriching solidarity, supplanting bulky welded joints with ceaseless twists achievable through progressed methods like rotational draw twisting or mandrel-assisted forms. It permits for both stylish creativity and designing productivity in a wide extend of indoor and open air environments.

What Makes Square Metal Tubing Ideal for Curved Applications?

Unlike circular bending square metal tubing offers a level surface profile, which is not as it were structurally particular but basically strong. When bowing square metal tubing, exactness and consistency are significant due to the tubing’s sharp edges and rise to measurements on all sides. High-quality aluminum grades (1100, 3003, 5005, 6063) permit for smooth misshapening without collapsing or wrinkling, particularly when pre-treated with PVDF or PE surface coatings. Its ordinary thickness range—from 0.6 mm to 5.0 mm—offers choice flexibility, whether creating light ceiling components or strong railing frameworks. Moreover, custom measuring and shifted radii alternatives offer assistance meet both enriching and load-bearing needs.

Where Is Square Tubing Bending Commonly Used?

Curved square tubing is fundamental in a wide cluster of present day applications. For occasion, enriching applications in inn halls utilize bowed tubes for staircase railings and chamber curves. Open spaces like parks include striking, bended entryways created from accurately bowing square metal tubing, making natural and welcoming visual openings. In flying center points and social centers, bowed tubing is utilized for ceiling systems that resound engineering bends whereas remaining fundamentally effective. These boards are lightweight, high-strength, and simple to introduce, much obliged to optimized tube shaping bolstered by point by point creation drawings.

What Are the Best Methods for Bending Square Metal Tubing?

What Is the Most Accurate Technique for Bending Square Tubes?

The most broadly utilized and exact strategy for twisting square metal tubing is rotating draw bowing. This strategy employments a settled sweep kick the bucket and a counter weight pass on to guarantee the tube twists cleanly without distorting the cross-section. It’s compelling for tight radii and is perfect for unmistakable components in railings or tasteful shows. For more slender tubing (like 0.6 to 1.5 mm aluminum), the utilize of a mandrel interior the tube can offer assistance avoid collapse or wrinkling. This handle is particularly critical in building settings where the visual smoothness and dimensional exactness of the twist must meet amazingly tall standards.

Can Heat Be Used When Bending Square Metal Tubing?

Yes, heat-assisted twisting is now and then utilized when bending square metal tubing, especially for thicker dividers or more tightly twists that chance breaking. Aluminum combinations such as 6063 and 5005 react well to direct warm, which makes the bowing handle smoother and makes a difference hold tube judgment. Be that as it may, overheating ought to be dodged as it seem compromise the mechanical properties. Controlled warming makes a difference decrease spring-back and guarantees smoother bends. This approach is especially profitable in custom structural pieces like enhancing openings and domed ceiling outlines, where nonstop, natural lines are fundamental for visual coherence.

What Role Do Mandrels Play in Bending Precision?

Mandrels are fundamental devices when bowing square metal tubing for applications requiring tight interior radii or tall stylish quality. Situated interior the tubing amid the bowing handle, mandrels offer assistance keep up the inner shape, anticipating divider collapse or deformations. Their utilize is common when creating public-facing components like staircase rails in inn halls or gathering lobbies. This strategy comes about in clean, wrinkle-free bends that keep up the tube’s keenness. Particularly in high-traffic regions, a smooth, ceaseless bend is best not fair outwardly but moreover practically, advertising less push focuses and a more damage-resistant wrap up.

How to Ensure Quality and Longevity When Bending Square Metal Tubing?

Does Surface Treatment Affect the Bending Process?

Absolutely. Surface treatments like PVDF or PE coatings do more than increase the aesthetics—they enhance durability and can reduce surface deformation during bending square metal tubing. Pre-treated surfaces also resist scratches, corrosion, and UV damage, which is essential for semi-outdoor applications like covered patios or entrance arches. Manufacturers must ensure that the bending process does not crack or damage the film. This is achieved through smooth die surfaces and precise pressure control. These coatings are also available in RAL colors and customizable hues, maintaining both functional and artistic requirements across any project.

How to Select the Right Aluminum Grade for Bending?

Aluminum alloy selection greatly influences the success of bending square metal tubing. Frequent choices include 1100, 3003, 5005, and 6063—which each offer a balance of formability and strength. For example, 6063 is often chosen in architectural frameworks due to its excellent extrusion qualities and good anodizing finish. Thinner gauges (0.6–1.5 mm) are better for decorative ceiling curves, while thicker sections (up to 5 mm) are ideal for structural uses like railings or load-bearing archways. Selecting the proper grade ensures the tubing bends without cracking or weakening, maintaining a long service life of up to 30 years.

What Installation Precautions Should Be Taken Post-Bending?

Once bending square metal tubing is complete, proper installation ensures longevity and visual consistency. Since the tubing is often customized, detailed construction drawings are necessary for accuracy. Fastening systems should accommodate the tubing’s curvature to avoid stress fractures during fixing. Transportation must also be planned carefully—the curvature must be protected from mechanical stress that could alter the bend. With panels or tubes quantified to project-specific lengths and radii, it’s critical that every segment is pre-fitted before onsite anchoring to ensure seamless installation and aesthetic flow.

Conclusion

Bending square metal tubing unlocks limitless architectural possibilities. From elegant stair railings to sweeping ceiling arcs, precision bending allows durable aluminum to take on fluid, organic shapes that enhance both function and form. Combined with proper material selection and surface treatment, the results are beautiful, structurally sound, and long-lasting. Guangdong Zhongchuang Building Decoration Materials Co., Ltd. specializes in processing high-quality square and custom aluminum tubing, offering precise manufacturing and expert support. Contact [email protected] today to discuss how to bring your vision to life with architectural-grade bent tubing.

FAQ

Can bending square metal tubing cause structural weakness?

No, when bent properly using mandrels or controlled methods, square tubing maintains its strength and integrity.

What aluminum grades are best for bending applications?

Grades like 6063, 3003, and 5005 are highly recommended for their ductility and strength.

Is it more difficult to bend square tubing than round tubing?

Yes, square tubing requires special attention to prevent collapse or wrinkling on the flat surfaces and corners.

Can bent aluminum tubing be used outdoors?

Absolutely. With proper coatings like PVDF, bent aluminum tubing performs well even in semi-exposed applications.

Is custom bending available in small quantities?

Yes, many manufacturers accept low MOQs such as 50m, especially when working with custom radii and sizes.

References

1. Aluminum Design Manual – Aluminum Association, 2024 Edition

2. Architectural Metals: A Guide to Selection, Specification, and Performance – L. William Zahner

3. Modern Metalworking Techniques for Architecture – Architect Journal, 2023

4. Advanced Metal Forming and Bending Methods – Journal of Structural Engineering

5. Sustainable Construction Practices Using Aluminum – Green Architecture Forum, 2024

6. Precision Bending of Aluminum Tubing – Manufacturing Engineering Magazine, 2025

_1762768699969.webp)