Aluminum Honeycomb Panels Favored in High-end Fields, Green Building Materials Market Potential Highlighted

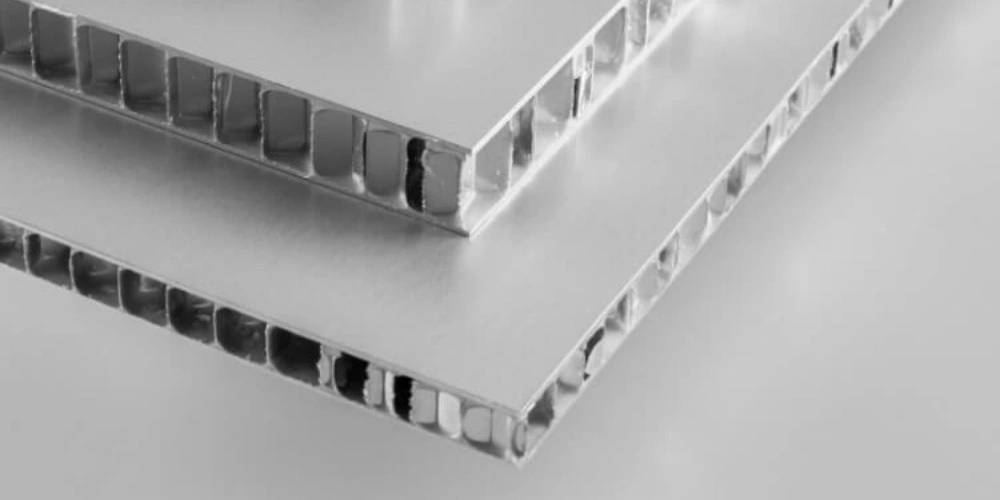

With the core advantages of "high strength + lightweight", the market share of aluminum honeycomb panels in the high-end building materials market continues to rise, and they are widely used in fields with strict material performance requirements such as villa exterior walls, ship interiors and high-speed rail carriages. Aluminum honeycomb panels use aluminum alloy as the face sheet and back sheet, with a honeycomb-shaped aluminum core in the middle. Their weight is only 1/5 of traditional panels, but their compressive strength is more than 3 times that of solid wood panels. They also have excellent heat insulation, sound insulation and fire resistance, and can adapt to complex environments such as high temperature and humidity.

Under the green development trend, the environmental protection attribute of aluminum honeycomb panels is further highlighted. Their material can be 100% recycled, and the production process has low energy consumption and less pollution, which meets the requirements of the national "double carbon" policy. At present, many domestic enterprises have realized the large-scale production of aluminum honeycomb panels, and launched ultra-thin and ultra-wide products through technological innovation to meet the customization needs of different high-end scenarios. Industry forecasts show that the market size of aluminum honeycomb panels will maintain an average annual growth rate of more than 12% in the next five years, becoming an important growth point in the green building materials field.

_1762768699969.webp)