Name:Aluminum insulated panels

Application scenarios:shopping malls, hotels, airports, high-speed rail stations, office buildings, etc

Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-20 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

Premium Aluminum Insulated Panels - Energy-Efficient Building Solutions

When you're looking for superior thermal performance and energy efficiency in your construction project, aluminum insulated panels offer the perfect solution. These imaginative composite boards combine two layers of high-grade aluminum sheets with progressed center materials like polyurethane froth, shake fleece, or glass fleece. This special sandwich development conveys extraordinary cover properties that can significantly decrease your warming and cooling costs. Whether you're building shopping shopping centers, inns, air terminals, or office buildings, these boards give exceptional warm obstructions whereas keeping up auxiliary astuteness and stylish offer for decades.

What Makes Our Insulated Aluminum Panels Special?

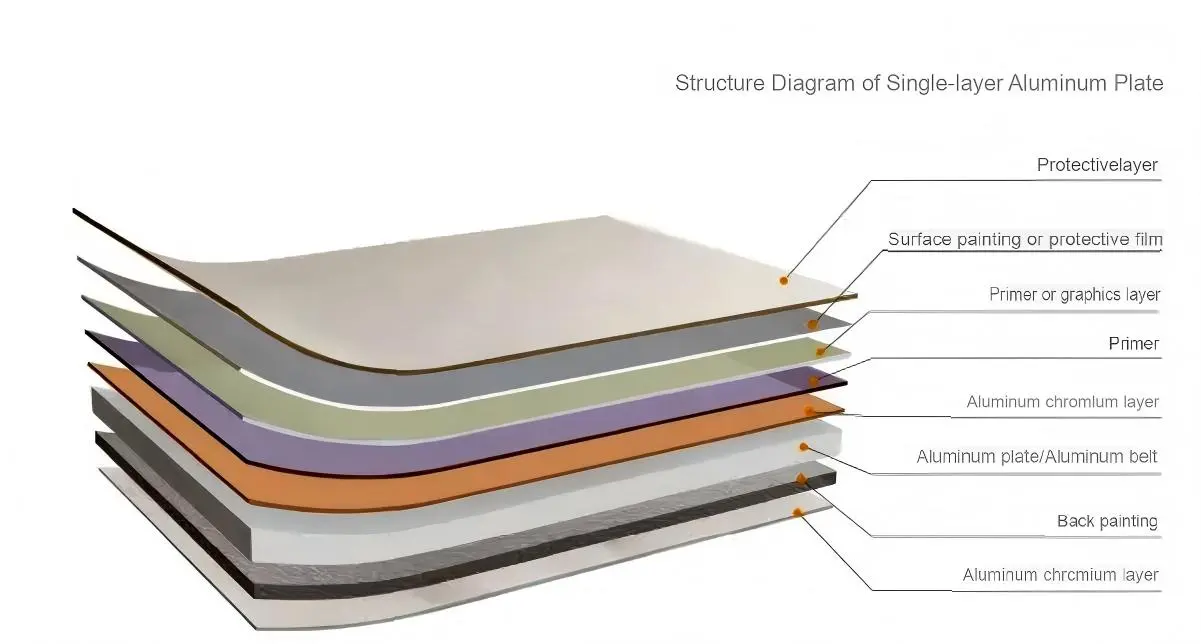

Our boards include a modern three-layer plan that sets them separated from routine building materials. The external aluminum layers give solidness and climate resistance, whereas the protection center conveys predominant warm performance.

You'll advantage from great sound separator properties that make calmer, more comfortable indoor situations. The fire-resistant characteristics guarantee upgraded security for tenants. Also, the lightweight however solid development diminishes basic stack requirements.

We fabricate these boards with premium materials counting 1100, 3003, 5005, and 6063 aluminum combinations. The thickness ranges from 1.5mm to 5.0mm, giving you adaptability for diverse applications. Our PVDF and PE surface medicines guarantee long-lasting color maintenance and climate resistance.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Versatile Applications for Modern Construction

These protects composite boards exceed expectations in assorted building applications. You can utilize them for outside dividers, material frameworks, and exterior cladding over different venture types.

Industrial offices advantage from the panels' vigorous development and warm proficiency. Stockrooms and cold capacity offices depend on their predominant cover properties. Private ventures appreciate the vitality investment funds and appealing wraps up accessible in RAL colors and custom options.

High-traffic commercial spaces like air terminals and high-speed rail stations select these boards for their toughness and moo upkeep necessities. The clean, proficient appearance suits cutting edge engineering plans perfectly.

Quality Standards and Certifications

We keep up strict quality guidelines sponsored by universal certifications counting CE, UL, SASO, and ISO 12944-6. These accreditations illustrate our commitment to brilliance and worldwide compliance.

Color consistency and gleam consistency meet exact determinations. Our corrosive resistance testing and scraped area resistance guidelines ensure long-term execution in challenging situations.

Sustainable and Cost-Effective Solutions

Energy efficiency drives real cost savings for building owners. These aluminum insulated panels significantly reduce HVAC operational costs through superior thermal performance. The 30-year warranty period provides long-term value and peace of mind.

Our fabricating prepare emphasizes maintainability and natural obligation. The boards contribute to green building certifications and energy-efficient development standards.

The recyclable aluminum components adjust with circular economy standards. This naturally cognizant approach decreases squander and bolsters economical development hones.

Production process

Custom Solutions for Your Project

Each venture has one of a kind necessities. We offer customized measuring, colors, and setups to coordinate your particular needs. Our least arrange amount of fair 30㎡ makes us available for ventures of different scales.

With our month to month supply capacity of 50,000㎡, we can handle large-scale ventures productively. Standard conveyance times of 15-20 days keep your development plan on track.

Our one-stop arrangement approach covers everything from introductory plan interview through last establishment back. This comprehensive benefit show streamlines your obtainment handle and guarantees reliable quality guidelines.

Ready to enhance your building project with premium aluminum insulated panels? Contact our technical team at [email protected] for detailed specifications, pricing, and custom solutions tailored to your requirements.

_1762768699969.webp)