Name:Hyperbolic aluminum plate

Application scenarios:shopping malls, hotels, airports, high-speed rail stations, office buildings, etc

Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size:Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-20 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

Hyperbolic Aluminum Plate: Advanced Architectural Solutions for Modern Buildings

When you're looking to create stunning, complex architectural shapes that make a lasting impression, hyperbolic aluminum plate is your go-to solution. This special-shaped aluminum product features a distinctive double-curved surface that transforms ordinary buildings into architectural masterpieces. With advanced manufacturing processes and superior material properties, these innovative panels help you achieve unique designs that were once impossible to create. Whether you're designing shopping malls, hotels, airports, or office buildings, this cutting-edge material delivers both form and function.

What Makes Our Curved Aluminum Panels Special?

Our double-curved aluminum items stand out in the development industry through imaginative fabricating methods. We utilize numerical control twisting and extending forms that guarantee uncommon accuracy. Each board meets strict quality measures with smoothness resistances inside 0.5mm.

The fabric determination incorporates high-grade aluminum amalgams like 1100, 3003, 5005, and 6063. These combinations give fabulous mechanical properties and long-lasting toughness. Your extend benefits from materials that stand up to erosion, keep up auxiliary judgment, and perform dependably for decades.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Applications Across Multiple Industries

Shopping centers benefit tremendously from these curved panels. The flowing surfaces create inviting environments that draw visitors and enhance the shopping experience. Hotels use these materials to establish distinctive facades that set them apart from competitors.

Airport terminals particularly appreciate the modern aesthetic these panels provide. The curved surfaces complement the dynamic nature of air travel while maintaining practical functionality. High-speed rail stations also utilize these materials to create impressive architectural statements.

Office buildings gain significant visual impact through strategic placement of hyperbolic aluminum plate installations. The panels can transform standard rectangular structures into dynamic, eye-catching developments that attract tenants and visitors alike.

Installation and Support Services

We give comprehensive back all through your venture lifecycle. Our administrations incorporate CAD 3D modeling that makes a difference you visualize the last result some time recently fabricating starts. Fabric mechanics recreation guarantees ideal execution beneath anticipated loads and natural conditions.

Factory pre-assembly testing distinguishes potential issues some time recently establishment. This proactive approach anticipates exorbitant delays and guarantees smooth on-site establishment. Our specialized group gives nitty gritty development drawings and on-site direction when needed.

The establishment prepare gets to be clear with our bolster. We supply nitty gritty informational and stay accessible for interview all through development. This comprehensive approach minimizes establishment time and decreases potential complications.

Quality Assurance and Certifications

Our fabricating forms meet universal measures counting CE, UL, SASO, and ISO 12944-6 certifications. These certifications illustrate our commitment to quality and security over worldwide markets.

Surface coating quality gets specific consideration in our generation prepare. We keep up strict measures for appearance quality, guaranteeing no splits, coating absconds, or color irregularities. Film thickness midpoints 50μm with least neighborhood thickness of 34μm for ideal protection.

Adhesion testing accomplishes review 0 comes about through cross-cut testing strategies. Hardness appraisals surpass 2H guidelines, giving great resistance to surface harm. Corrosive resistance testing affirms solidness in challenging natural conditions.

Environmental Benefits and Sustainability

Aluminum's recyclability makes these boards an ecologically mindful choice. The fabric can be reused more than once without losing its basic properties. This characteristic adjusts with advanced supportability objectives and green building standards.

Energy proficiency moves forward through legitimate establishment of the item frameworks. The materials give fabulous warm execution whereas keeping up basic astuteness. Your building benefits from decreased vitality utilization and made strides tenant consolation.

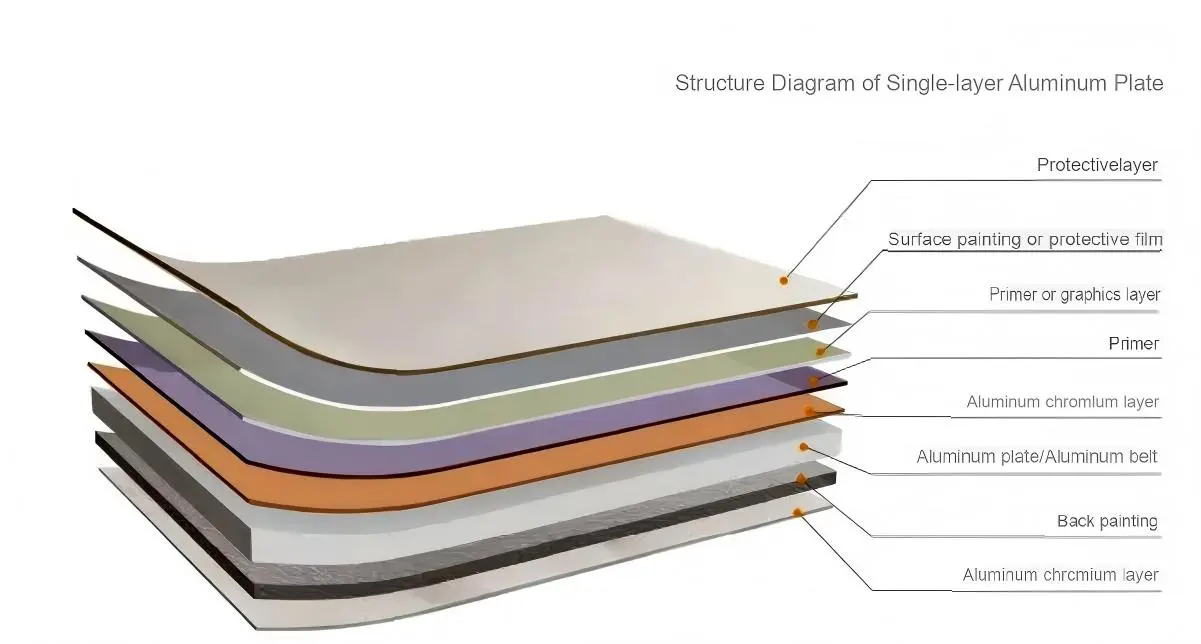

Production process

Ordering Information and Lead Times

Our minimum order quantity starts at 30 square meters, making our products accessible for various project sizes. Standard delivery times range from 15-20 days depending on customization requirements and order complexity.

We offer a comprehensive 30-year warranty on our products, demonstrating confidence in material quality and manufacturing processes. This warranty provides peace of mind and protects your investment over the long term.

For technical specifications, project consultation, or ordering information, contact our team at [email protected]. We're ready to help you transform your architectural vision into reality with premium hyperbolic aluminum plate solutions that exceed expectations and deliver lasting value.

_1762768699969.webp)