Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-25 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

Insulated Aluminium Cladding: High-Performance Building Solutions

Superior Energy Efficiency for Modern Buildings

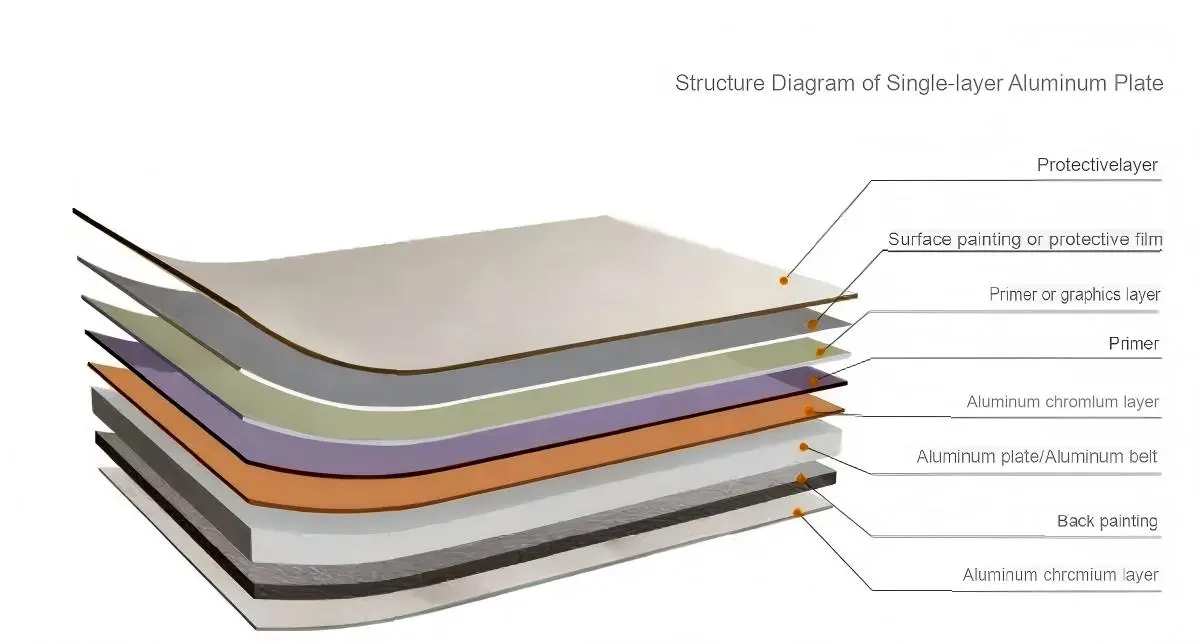

When you're looking for building materials that deliver both performance and sustainability, insulated aluminium cladding stands out as the perfect solution. This innovative composite material combines the strength of aluminum with the thermal efficiency of insulation cores, creating a single panel that streamlines your construction process. Our product features aluminum sheets bonded to high-performance insulation cores like polyurethane foam or mineral wool, delivering exceptional R-values while maintaining the durability you need for long-term projects.

The sandwich structure design offers you unmatched thermal performance. You'll appreciate how the aluminum outer layer protects against weather and impact, while the insulation core significantly reduces heat transfer. This combination can lower your heating and cooling costs by up to 30% in extreme climates.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Streamlined Installation Process

Installation becomes remarkably efficient with our system. The interlocking panel design creates tight seals while allowing for thermal expansion. You'll receive detailed construction drawings and technical guidance throughout your project.

Our engineering team provides comprehensive support including:

- CAD 3D modeling for precise planning

- Material mechanics simulation for optimal performance

- Factory pre-assembly when applicable

- On-site technical guidance ensuring ±0.5mm accuracy

Versatile Applications Across Industries

Whether you're working on private homes, commercial workplaces, or mechanical distribution centers, these boards adjust to your particular prerequisites. Cold capacity offices especially advantage from the uncommon warm boundary properties. The fabric performs astoundingly in both hot and cold climates, making it perfect for different geographic locations.

The lightweight nature diminishes basic stack necessities whereas keeping up predominant quality characteristics. This interprets to potential investment funds in establishment and surrounding costs for your projects.

Environmental and Economic Benefits

Choosing this arrangement underpins your maintainability objectives. The aluminum components are completely recyclable, and the progressed vitality proficiency contributes to diminished carbon impressions. The expanded benefit life minimizes substitution needs, advance improving natural benefits.

Performance Standards:

- Film thickness averaging ≥50μm for long-term protection

- Cross-cut adhesion testing at grade 0

- Hardness rating ≥2H for impact resistance

- Acid resistance testing with 5% HCl for 24 hours

- Minimum 10-year coating warranty

Quality Manufacturing Standards

Each board meets exacting quality prerequisites. The appearance quality guarantees no splits, coating peeling, or color irregularities. Surface medicines experience comprehensive testing counting sparkle estimation, attachment confirmation, and scraped spot resistance evaluation.

Our fabricating office keeps up reliable generation benchmarks with conveyance times extending from 15-25 days. The least arrange amount of 30㎡ makes our insulated aluminium cladding available for ventures of different scales.

Custom Solutions for Your Project Needs

We get it that each venture presents one of a kind challenges. Our group works closely with you to create scenario-based arrangements that address your particular prerequisites. From introductory concept through establishment and upkeep, we give full-cycle support.

The combination of fabric development and predominant execution makes our items stand out in competitive markets. Green and economical esteem recommendations adjust with advanced building measures and future administrative prerequisites.

Production process

Professional Support and Expertise

Our technical team brings decades of experience in architectural decoration materials. We stay current with industry developments and building code requirements to ensure your projects meet all necessary standards.

Contact us at [email protected] to discuss your project requirements. Our insulated aluminium cladding solutions deliver the performance, efficiency, and reliability your building projects demand. Transform your construction approach with materials that combine innovation, sustainability, and proven results.

_1762768699969.webp)