Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-77 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

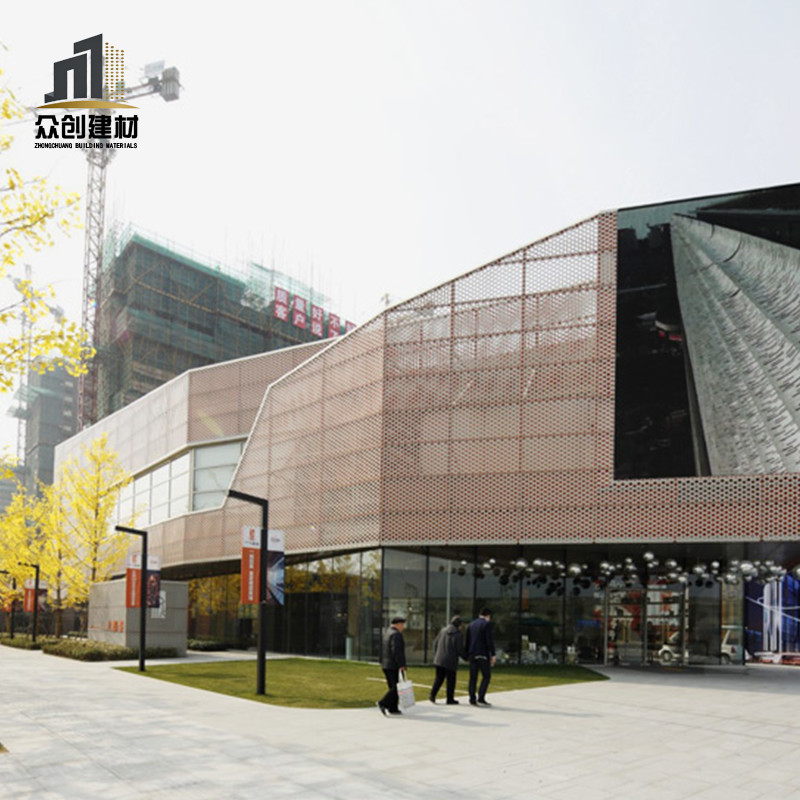

Perforated Aluminum Curtain Wall: Transform Your Building with Style and Function

Are you looking for a façade solution that combines stunning visual appeal with practical benefits? Our perforated aluminum curtain wall systems offer the perfect blend of artistry and functionality. These innovative panels feature precision-drilled holes that create dynamic light effects while providing excellent ventilation and privacy control. Your building deserves a façade that stands out, and our custom-designed aluminum panels deliver exactly that. With decades of experience in architectural decoration, we understand what makes buildings truly remarkable. Whether you're designing a commercial complex, sports facility, or cultural center, our perforated solutions transform ordinary exteriors into extraordinary architectural statements.

Why Choose Our Perforated Aluminum Curtain Wall Systems?

Advanced Material Technology

Our aluminum boards utilize premium grades counting 1100, 3003, 5005, and 6063 amalgams. These materials offer extraordinary quality whereas keeping up lightweight properties. The thickness ranges from 1.5mm to 5.0mm, guaranteeing your particular venture necessities are met perfectly.

Precision Perforation Technology

We utilize CNC laser cutting innovation to make gaps extending from 1/8 inch to 2 inches in breadth. The designs can be circular, square, or totally custom plans that reflect your brand character. This exactness guarantees each board meets our strict quality measures with extend blunders ≤0.5mm.

Superior Surface Protection

Our PVDF and PE coating frameworks give extraordinary climate resistance. The coating meets rigid quality benchmarks with normal film thickness ≥50μm and hardness ≥2H. This assurance guarantees your façade keeps up its excellence for decades, supported by our 30-year guarantee.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Functional Benefits That Matter

Climate Control Excellence

The strategic perforations in our perforated aluminum curtain wall panels allow controlled airflow while reducing solar heat gain. This natural ventilation reduces your building's energy consumption significantly. In sunny climates, the panels effectively minimize glare while allowing pleasant natural light to filter through.

Artistic Light Effects

During daylight hours, the perforated patterns create beautiful shadow play on interior surfaces. At night, interior lighting transforms your building into a glowing architectural masterpiece. The perforations act as tiny spotlights, creating a dynamic display that changes throughout the evening.

Brand Integration Opportunities

Custom perforation patterns can incorporate your company logo or artistic motifs. This integration makes your building an extension of your brand identity. The patterns become conversation starters and memorable landmarks in your community.

Quality Assurance You Can Trust

International Certifications

Our products carry CE, UL, SASO, and ISO 12944-6 certifications. These certifications demonstrate our commitment to international quality standards and safety requirements.

Comprehensive Testing Standards

Every panel undergoes rigorous testing including:

- Cross-cut adhesion tests (Grade 0 performance)

- Acid resistance testing (5% HCl for 24 hours)

- Abrasion resistance verification (6.6L/μm)

- Weather resistance evaluation

Professional Installation Support

We give point by point development drawings and CAD 3D modeling for each extend. Our production line pre-assembly administrations and on-site specialized direction guarantee immaculate establishment. Fabric mechanics reenactment makes a difference anticipate execution some time recently establishment starts.

Applications Across Industries

Commercial Buildings

Shopping centers and office complexes benefit from the energy efficiency and striking appearance. The product systems reduce cooling costs while creating memorable architectural features.

Sports Facilities

Stadiums and recreation centers require both functionality and visual impact. Our panels provide excellent ventilation for spectator comfort while creating distinctive exterior designs.

Cultural Buildings

Museums, theaters, and community centers use our systems to create artistic façades that reflect their cultural mission. Custom perforation patterns can tell stories or represent cultural symbols.

Our Complete Service Approach

We offer end-to-end arrangements from introductory plan interview through last establishment. Our group works closely with designers and temporary workers to guarantee consistent venture execution. Manufacturing plant pre-assembly decreases on-site establishment time and potential errors.

Material choice direction makes a difference you select the ideal aluminum review for your particular climate and stylish prerequisites. Color coordinating administrations guarantee your façade flawlessly complements your by and large plan vision.

Get Started on Your Project Today

Ready to transform your building's exterior? Our perforated aluminum curtain wall solutions combine cutting-edge technology with artistic design possibilities. Contact our team at [email protected] to discuss your specific requirements and receive a customized proposal that brings your architectural vision to life.

_1762768699969.webp)