Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-82 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

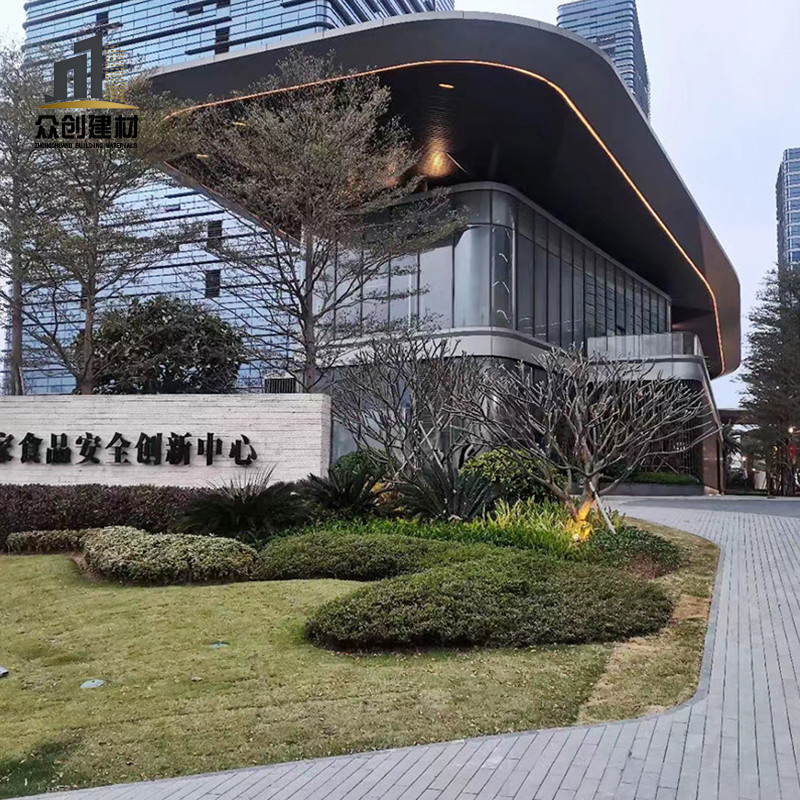

Twisted Aluminum Panels: Sculptural Architectural Solutions That Transform Spaces

Looking for architectural panels that combine artistic beauty with structural reliability? Our Twisted Aluminum Panels blend industrial precision with sculptural expression, creating three-dimensional dynamism for your building facades, ceilings, and installations. These innovative panels transform ordinary surfaces into architectural art, offering twist angles from 10-180 degrees per meter to achieve unique, custom-designed shapes that make your project stand out.

What Makes Our Twisted Aluminum Panels Unique?

Advanced Manufacturing Process

We craft each panel using high-grade aluminum alloys (1100, 3003, 5005, 6063) with thickness ranging from 1.5-5.0mm. Our specialized manufacturing process begins with computer-controlled equipment that precisely twists the aluminum along single or multiple axes.

Before twisting, we pre-treat the aluminum through annealing at 415°C, which softens the metal for smooth deformation without cracking. After achieving the desired spiral shape, we apply secondary heat treatment to restore hardness and ensure long-term shape retention.

Superior Surface Treatments

Your panels receive professional PVDF/PE coating systems that exceed industry standards. Our surface treatments offer:

- Film thickness: Average ≥50μm, minimum local ≥34μm

- Hardness rating: ≥2H for scratch resistance

- Adhesion grade: 0 (highest performance level)

- Acid resistance: Withstands 5% HCl for 24 hours

- Color options: RAL colors and custom finishes

Applications That Inspire

Landmark Architecture

Make capable building articulations with huge bent boards for high rise passages, exhibition hall veneers, or corporate base camp. The sculptural flexibility permits you to symbolize development, development, or your brand's interesting identity.

Interior Plan Excellence

Transform lodgings, lounges, and commercial spaces with littler turned boards as central focuses. Driven backlighting highlights the winding forms, making shocking visual impacts that charm visitors.

Public Craftsmanship Installations

Parks and squares advantage from these boards in sculptural establishments. Light passing through turned surfaces makes ever-changing shadow designs all through the day.

Why Choose Our Twisted Aluminum Panels?

Structural Integrity Meets Art

Our high-strength alloys maintain shape integrity after twisting in Twisted Aluminum Panels, resisting deformation under gravity and wind loads. This ensures your architectural investment remains beautiful and functional for decades.

Interactive Light Effects

The twisted surfaces refract light at varying angles, creating dynamic shadows that change with sun position. This natural light interaction adds life to static architectural elements.

Comprehensive Service Support

We provide full-cycle support from conceptual design to installation guidance. Our services include:

- CAD 3D modeling and design consultation

- Material mechanics simulation

- Factory pre-assembly testing

- On-site technical guidance

- Project precision guarantee: ≤0.5mm tolerance

Environmental Responsibility

Our aluminum boards back feasible building hones. Aluminum is 100% recyclable, and our fabricating forms minimize natural affect whereas conveying uncommon solidness.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Installation and Maintenance

We supply point by point development drawings and custom-made brackets for secure establishment. Our specialized group gives on-site direction to guarantee legitimate mounting that keeps up the visual impact of drifting figures whereas concealing hardware.

The weather-resistant coatings guarantee open air establishments hold their shape and wrap up indeed after decades of presentation, with negligible upkeep necessities.

Quality Assurance

Every panel meets stringent quality standards with comprehensive testing for appearance, coating thickness, gloss consistency, adhesion, hardness, and chemical resistance in Twisted Aluminum Panels. Our ISO 12944-6 certification guarantees corrosion resistance performance.

Ready to transform your architectural vision into reality? Contact our design team at [email protected] to discuss your project requirements and receive custom solutions tailored to your specifications.

_1762768699969.webp)