Thickness:1.5-5.0mm

Material:1100, 3003, 5005, 6063, etc

Surface treatment:PVDF/PE

Supply capacity:50000 ㎡/month

Service life:30-year warranty

Minimum Order Quantity (MOQ):30㎡

Color:RAL and other customized colors

Size Customized size

Feature:Durable, easy to install, environmentally friendly, high-quality

Certificate:CE,UL,SASO,ISO 12944-6

Delivery time:15-20 days

Installation Guide:Provide detailed construction drawings

Place of Origin:Guangdong, China

- Product Description

Vertical Aluminum Siding Panels: Premium Building Exterior Solutions

Looking to transform your building's facade with a modern, sleek appearance? Vertical aluminum siding panels offer the perfect combination of durability, style, and weather resistance for today's architectural demands. These elongated aluminum cladding products are specifically engineered for vertical installation, creating striking linear profiles that emphasize height and contemporary design. Whether you're working on residential homes or commercial buildings, our products deliver exceptional performance with minimal maintenance requirements. With thickness options ranging from 1.5-5.0mm and premium materials like 1100, 3003, 5005, and 6063 aluminum alloys, these panels provide lasting value for your investment.

Why Choose Our Vertical Aluminum Cladding Solutions?

Superior Material Innovation

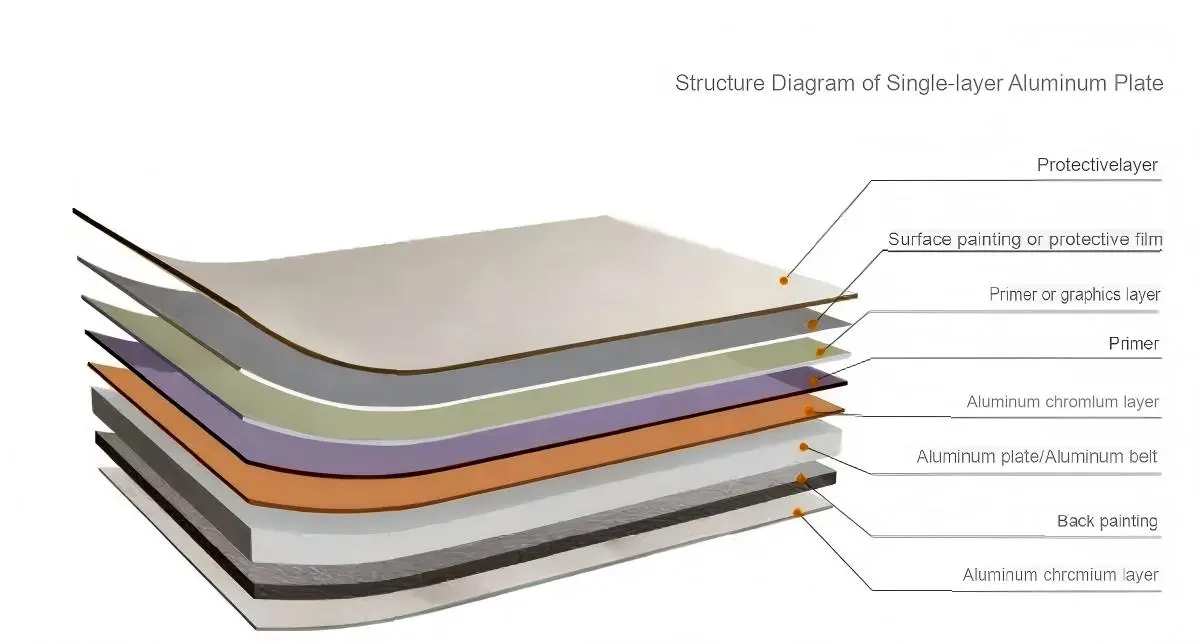

Our aluminum boards include progressed building that sets them separated from standard outside cladding. The unbending aluminum center avoids twisting and drooping over time. Surface medicines incorporate PVDF and PE coatings that stand up to UV blurring and erosion for decades.

The vertical introduction actually channels water descending. This plan diminishes dampness buildup behind the siding. Your building remains secured in overwhelming precipitation regions.

Customization That Meets Your Vision

Every extend merits a one of a kind approach. We give one-stop arrangements from beginning plan concepts to last establishment direction. Our group underpins you through CAD 3D modeling and fabric mechanics simulation.

Color choices incorporate RAL benchmarks additionally custom colors to coordinate your plan topics. Board sizes are completely customizable to fit your particular building prerequisites. Our exactness fabricating guarantees venture mistakes remain inside 0.5mm tolerance.

Professional Installation Support

Installing outside boards shouldn't be complicated. We give nitty gritty development drawings with each arrange. Our specialized direction makes a difference temporary workers total establishments efficiently.

The interlocking edge plan avoids water penetration whereas disentangling the establishment prepare. Adjusted lines decrease labor time compared to conventional siding materials.

Surface coating quality standards

|

Serial Number

|

Item

|

Standard Requirements

|

|

01

|

Appearance Quality

|

No cracks or weld breaks on either side of the aluminum material; no coating peeling or cracking. The appearance is clean and the color is basically consistent, with no obvious scratches. The decorative surface has no obvious indentations, marks, or unevenness. No obvious color changes; the coating has no flow marks, cracks, bubbles, inclusions, or other surface defects.

|

|

02

|

Film Thickness

|

Average film thickness ≥ 50μm, minimum local film thickness ≥ 34μm.

|

|

03

|

Gloss Deviation

|

Gloss range 31.0~33.9, average 32.0

|

|

04

|

Adhesion

|

Cross-cut test, grade 0

|

|

05

|

Hardness

|

≥2H

|

|

06

|

Acid Resistance

|

5% HCl, 24h, no change

|

|

07

|

Abrasion Resistance

|

6.6L/μm

|

|

08

|

Warranty Period

|

≥ 10 years

|

Applications and Design Benefits

Ideal Project Types

Modern residential homes benefit from the clean, upright visual effect. Commercial buildings achieve sophisticated facades that impress visitors and tenants. Both new construction and renovation projects can incorporate these panels seamlessly.

Urban environments present unique challenges. Our vertical aluminum siding panels minimize dirt accumulation compared to horizontal alternatives. This feature is perfect for busy areas with limited maintenance access.

Weather Resistance Advantages

Aluminum normally stands up to erosion and temperature vacillations. The vertical profile sheds water successfully, anticipating moisture-related issues. PVDF coatings keep up color consistency indeed beneath seriously UV exposure.

Wind resistance surpasses standard necessities for high-rise applications. The unbending development keeps up auxiliary judgment amid extreme climate occasions.

Order Information and Support

Flexible Ordering Options

- Minimum Order: 30㎡ to accommodate various project sizes

- Delivery Time: 15-20 days from order confirmation

- Origin: Manufactured in Guangdong, China

- Custom Colors: Available to match any design specification

Pre-Assembly Services

Our factory pre-assembly capabilities reduce on-site installation time. We simulate material mechanics before shipment to ensure perfect fit. This approach minimizes construction delays and cost overruns.

Production process

Environmental and Sustainability Benefits

Aluminum offers exceptional recyclability without performance degradation. Our products contribute to green building certifications. The long service life reduces replacement frequency and environmental impact.

Energy efficiency improves through proper thermal management. The air gap behind panels provides additional insulation value. This feature helps reduce heating and cooling costs over the building's lifetime.

Ready to elevate your building's exterior with premium vertical aluminum siding panels? Contact our team at [email protected] for detailed specifications and project consultation. We're here to help you achieve exceptional results.

_1762768699969.webp)